When you make as many wood box beams as we do, thousands every year, you learn a few things about great building techniques.

Joinery Strength: Spline-miter vs. Lock Miter

Spline-miter Corner Box Beam Joints

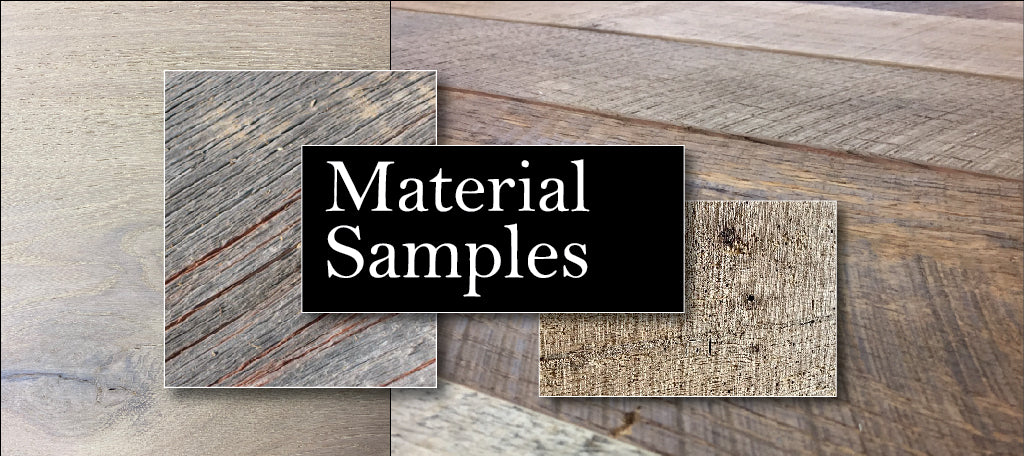

One area of focus for us in building our custom wood box beams is the strength and trueness of our mitered corner joinery, as in our reclaimed wood Rough Sawn, Resawn, or new Euro White Oak box beams. Getting the corners right is especially important when building with reclaimed wood since the intent is to mimic a solid wood beam. To truly create this effect the corners where two faces join should all but disappear.

Our Spline-miter Joint:

Lock Miter Box Beam Joints

For some projects we use the lock miter joint which is created using a special bit. The result creates a kind of tongue and groove mating surface between the to faces. This process, while fairly exacting it result can often take more time to set up the equipment that it actually takes to build the box beam. The strength of the joint is paramount but eliminating unnecessary delays is also a concern at our scale of business. That said, we opt for a spline-mitered corner joint. It’s a true mechanical lock which is reinforced with glue. The tolerances are narrow enough where the pieces mechanically lock without glue; the glue only adds to the long-term strength of the joint. Set up is quick and performance is solid—in tens of thousands of box beams we’ve never had one fail.

More About Spline-Miter Corner Joints

The spline provides long-grain surface area for more effective gluing, and it also creates a sturdy, self-aligning mechanical connection. Splines don’t have to be thick to be effective, but their placement in the joint is important. Unlike a lock miter lacking the spline, the addition of the spline is cut across the grain, so it is very strong from the opposing grains. The splined miter joint is going to be very strong. Splines increase the surface area being glued, and thus the strength of the joint. And since miter is close to being end-grain to end-grain, it benefits from this reinforcement. The increased joint strength is due to three factors: structural advantage, the thickness of the wood slivers used, and the glue surface area.

Know Who & How Your Wood Box Beams Are Made

#ItMatters

0 comments