What You Need To Know Before Buying A Wood Box Beam

Do you know what you need to know before buying a wood box beam?

You don't choose a wood box beam; you design one to be built. Learn everything you need to know before pulling the trigger. Reading this page, you will learn more about ceiling beams made with real wood box beams.

What is a wood box beam?

A wood box beam is a hollow beam made from real wood to replicate the look of a solid beam (like hand-hewn beams or rough-sawn beams). Box beams are generally not structural beams like a solid new wooden beam may be. The original faces of a solid beam or plank are joined together to form a hollow wood beam. A wood box beam can have 2, 3, or 4 sides depending upon how and where it will be used (and seen). Keep reading to learn more.

Some might call these hollow beams faux wood beams, but when you consider the level of craftsmanship that goes into creating a custom wood box beam, the term “faux wood beam” or “fake wood beam” really cheapens the effort in our view. Our box beams are not faux in any way, they are real wood.

What are box beams made of?

- All of our reclaimed wood box beams are made from domestically sourced, antique American reclaimed barn wood beams which are real wood. These solid beams were the solid timber frames of century-old American barns and historic structures.

- Although we made our name in reclaimed wood we have taken the market by storm by creating wood box beams from new Euro White Oak which elevate your design to another level.

- Part of the charm of reclaimed wood beams are the nail holes, and remnants of insect tracks (we fumigate and kiln dry all of our material so don't worry about bringing any creepy crawlies into your home)

- Another type of material box beams are constructed with are with reclaimed softwood, like Douglas Fir and Pine from horse corrals. These corral boards have a silver-gray appearance and have been a highly sought-after material for over a decade.

- The patina of reclaimed wood is what sets it apart from new wood that has been artificially distressed to look old. There's no story behind that material, while reclaimed wood has a rich history and engaging story to tell.

- As with a solid wood mantel, a wood box beam mantel makes for a great fireplace surround as a new wood mantel or to cover an existing mantel

- Our new wood box beams are generally made from hardwoods and our European white oak box beams are the most popular in this category.

- All of our boxed ceiling beams and boxed beam mantels are made to our client's specifications, with a custom color finish option on the new wood beams.

What kinds of are there?

There are countless types of wood box beams but all of our box beams are handmade to your specifications for your project in these materials:

- Rough Sawn beam

- Hewn beam

- Resawn beam

Our Euro White Oak is often chosen with a custom stain and finish and is becoming a popular choice to complement hardwood floors made in the same material and finish

If you would like a custom (colored) finish, please do not order from this listing. Instead, please call Shauna at (714) 557-9655 to discuss your project and arrange for samples to be made for your approval. A custom finish is an involved process, far outside the ability of a website to capture; and even, if possible, we'd prefer to work with you directly one-on-one.

What Species of Wood Box Beams Are There?

We produce box beams in a variety of wood species, but it usually comes down to texture choices which drive the client's preference. We offer red oak, white oak, and other mixed hardwoods including newly harvested Euro White Oak. Regardless of your material selection, our craftsmen with over 200 years of experience between them will create the perfect box beam for your custom project.

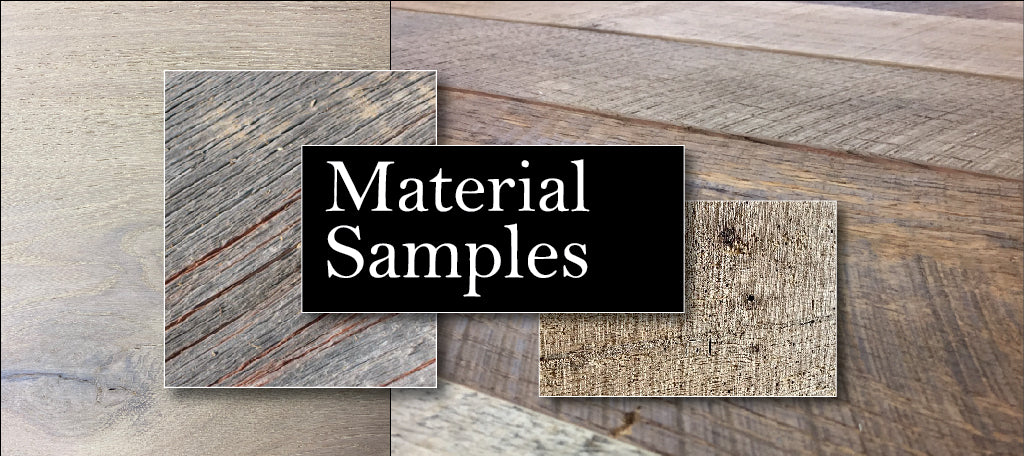

Types of reclaimed wood box beams (European white oak not shown):

Why Choose A Hand Hewn Box Beam?

While we love constructing wood box beams from both new and reclaimed wood, in hand hewn and rough sawn--and even resawn materials, but there is something special about a hand hewn box beam (made from hand hewn barn beams) because they bring greater visual intrigue into your room and give you a story to tell. Hand-hewn is a great choice if you're looking for a rustic fireplace mantel. Each of our hand-hewn reclaimed box beams is different from the next and has irresistible character and charm. Every axe mark tells the story of a pioneer over a century ago and his tenacity to build something bigger than himself. We offer both reclaimed box beams and a solid reclaimed wood beam, the latter available through our division TheMantelCollection.com which has the solid barn beam mantel in stock and ready to ship or pickup. Jump to our hewn here.

What Are Reclaimed Rough Sawn Box Beams?

With the advent and availability of powered, machine-driven circular and band saws, rough-sawn beams became ubiquitous. Timber milled, with circular or band saws a century ago often left behind circle saw or chatter marks, blade tooth impressions, and burn marks. As with any reclaimed material, part of the visual appeal is the staining and uneven coloration.

Rough Sawn (could also be referred to as 'circle sawn') is the term used to describe material cut into dimensional lumber by the use of a circular saw. Before the advent of--or use of--powered milling machinery, manpower was the force behind the tools (see our Hand Hewn box beams for that look). Rough-sawn material has the obvious circular saw marks; remnants of the tool used to cut it many generations ago.

The circular saw marks are caused by any number of things, including a bent tooth or blade, wobble in the feeding of the beam through the machine, and the list goes on. However, the marks were caused, and we're glad they were because this creates a clean look from the more square angles but keeps the historical interest and visual variety from the saw marks.

Design Your Rough Sawn Reclaimed Wood Box Beams Here.

What Are Reclaimed Resawn Box Beams?

When resawing the original face material away, the resawn beam core is what remains. This resawn core has a nearly smooth face on all sides. This is the ideal type of material to sand smooth and apply a stain or custom translucent finish, allowing the beautiful old-growth tight grain to show through. You'll still see an old nail hole here and there but the original face patina will have been removed. The species of a reclaimed wood box beam isn't as important as with our Resawn or Euro White Oak since the original face patina disguises the core material species. Should you wish to specify the species, however, we can offer white oak, red oak, softwoods, and heart pine. If you're looking for something specific please let us know. Our Architect, Designer, and Builder clients most often simply specify the color tone range and we pull material from there.

A Box Beam, not a glulam beam, not an LVL beam, is not made with an internal steel beam and is very much a real beam in its material construction since we use only authentic reclaimed wood for the construction.

Design Your Resawn Reclaimed Wood Box Beams Here.

Example of a Resawn Box Beam:

What are European White Oak Box Beams?

When creating a box beam from newly harvested wood, the process of creating a box beam is the same; resawing an appearance layer from a thicker plank, then engineering it to Baltic Birch, then joining the face panels together to form the intended shape. This is the box beam you'd choose if you want a custom finish like a floor has. With our in-house custom finish division, we have the experience and equipment to create the finish you envision. The most popular material is European White Oak, but we can provide any number of species for your project.

Design Your European White Oak Wood Box Beams Here.

Example of a (new wood) European Oak Box Beam::

How is a Different than a ?

To make a reclaimed barn wood hollow beam (or a faux wood beam mantel), we first resaw the original face material away from the core of reclaimed barn beams or boards (a thick veneer).

These original face skins are engineered to the finest Baltic Birch for strength and structure (for rough-sawn and resawn box beams, hand-hewn box beams are not engineered), then join the sections together, reinforcing the structure with internal blocking.

Using a mix of wood glue, biscuit joinery, and other fixtures (not wood screws though) the faces are joined into a secure structure.

Seeing the true artistry of a well-done reclaimed box beam is a real treat. Our Craftsmen can hide the corner and length seams and even cut in wood grain by hand so there is no discernable difference in grain at the joints. This is why our clients often think we hollowed out a solid beam to create their box beams because the joints are imperceptible.

How Big Can You Make a ?

There isn't a box beam size we haven't built. With our massive inventory and experience in architectural elements, we'll likely be able to create what others may not due to limitations in their material access or construction ability. Unlike what might be offered through the big box stores like Home Depot, or from a contractor not familiar with producing these works of art. We make ours with a solid piece of wood for each face, of original material for most sizes, even the long ones--not a fake handmade distressed finish. When it comes to box beam sizes, we can make almost anything your project requires. Choose a material texture and request a quote for your instant price.

We can make box beams as narrow as 2" for the face width and up to any depth and length.

Example of some Hand Hewn Box Beams that are nearly 33ft long:

Where are Used?

Choosing a custom-made box beam not only looks great but has functional appeal as well. Box beams are often what you see on ceilings. A box beam is also used to:

- Wrap an exposed ceiling beam or ceiling joist and are perfect in a vaulted ceiling

- Wrap unappealing structural elements like pipes or I- beams, any exposed beam, or the stick framing in a building.

- Installation is far easier than when using a solid real wood beam since they can be easily trimmed or modified to fit with tools on the job site, and the weight is far less than a solid new or reclaimed beam.

- Although we don't offer a wood stain for our reclaimed box beams, we do offer a custom finish with our Euro White Oak box beams.

- Box beams are often used for fireplace mantels because the perfect dimensions can be achieved

- As well, they are a great alternative to solid beams in applications that preclude the use of heavier solid beams. Basically, use a wood box beam anywhere the look of real beams are impractical but hollow beams are perfect.

Example of using Hand Hewn Box Beams as Ceiling Beams:

Do Cost the Same as a ?

The final cost depends on the beam, dimensions, and many more factors however a box beam is usually more expensive than a solid beam simply due to the extensive labor involved in crafting such a piece. This is in addition to the cost of the host beam from which the original face skin material is taken.

Take a look at our box beam product gallery in each of our product listings.

In the end, we can make the perfect box beam to complement your need, room and wall décor, and timeless style.

Example of Hand Hewn Box Beams being made (incomplete):

Looking to do a ?

Many homeowners choose a box beam (mantle) as a fireplace mantel because we can build to their exact dimensions. This also includes what might be called a mantel shelf and even floating shelves. We add the fire to a reclaimed wood fireplace. If you want to dress up a tired brick fireplace, a hollow or rustic faux beam mantel may just be the answer you're seeking.

Being lighter, a hollow box beam is easier to install and doesn't require hefty lag bolts. Check with your installer or the web for a variety of installation methods. We prefer the brackets from Shelfology which works well for both solid and hollow box beams and especially floating shelves.

Choosing a box beam as a floating mantel (or embedded such as in a brick mantel fireplace) is ideal when you need to precisely control the dimensions of the beam to fit within the mounting space. Unlike a solid beam, a wood box beam's dimensions are all within our control.

- With a solid beam, they are what they are, and to reduce the face of a solid beam means to cut off the original face which leaves a freshly cut face. This is in opposition to the other remaining original faces. With a box beam, we can construct it in a way to achieve the exact front face height, top and bottom face depths (or protrusion) as well as the length of the course.

- Wood box beams are a great way to hide existing structural supports or just to add to the room's aesthetic appeal. Box beams offer the look of solid beams with the benefits of custom sizing and lightweight installation.

- Box beams replicate the look of solid reclaimed timber beams but have improved workability and practicality: they're uniform in size throughout the length of the beam, are available in any length and width combination, and are lighter and easier to install than solid beams.

Jump To Our Box Beam Mantels Here for an Instant Price + Order