Authentic reclaimed barnwood beams, resawn for a smooth, refined surface with subtle saw marks.

Resawn box beams are crafted by cutting away the outer skin of historic hand-hewn or rough-sawn beams, revealing a cleaner face of wood. The result is a beam with a smoother texture while still carrying the story, character, and history of its past. Hollow by design, they’re lightweight, custom-made to your dimensions, and perfect for ceilings and architectural accents.

- Authentic reclaimed American barnwood core

- Smooth, resawn texture with subtle saw marks

- Hollow, lightweight construction

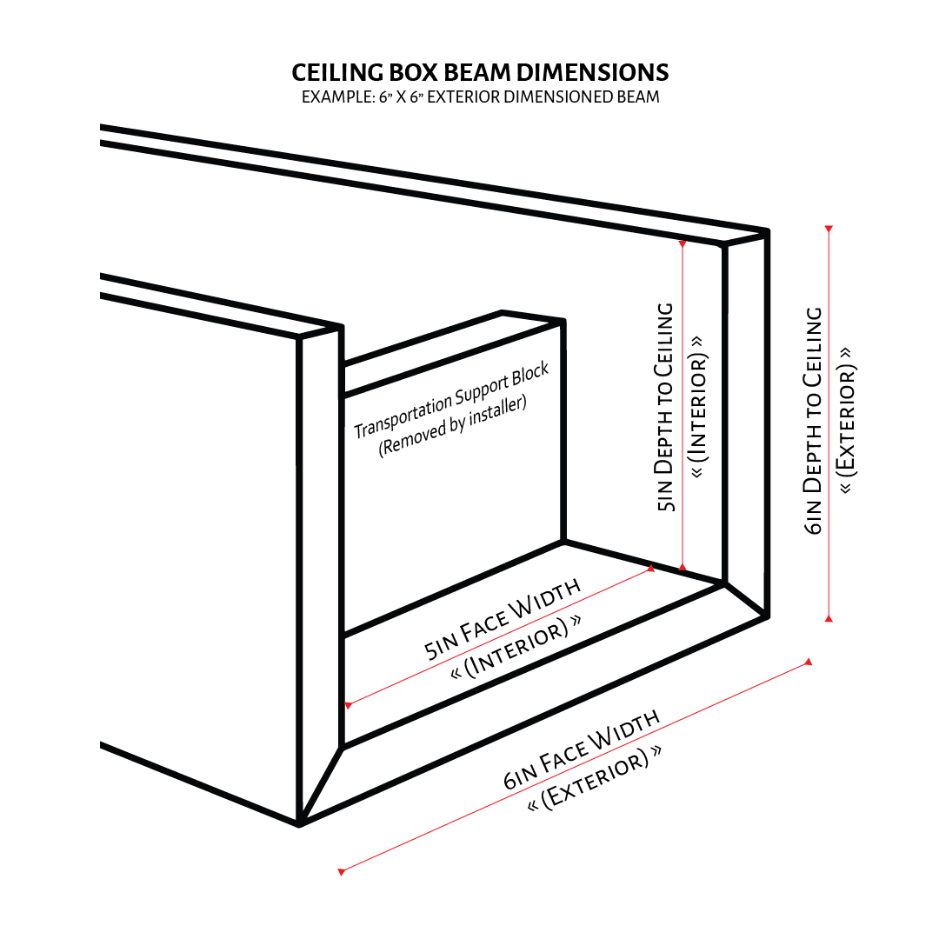

- Custom sizes: width, depth, and length

- Lead time: 8–12 weeks

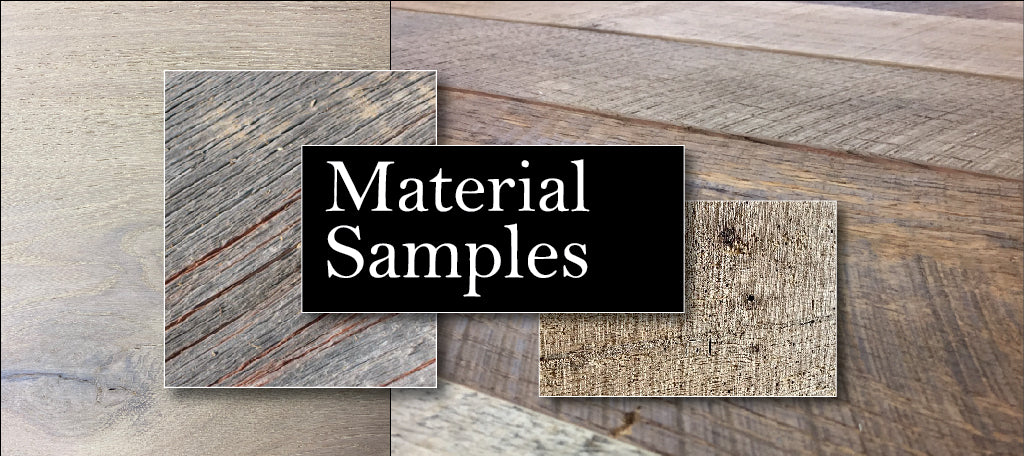

The Resawn Advantage

- Balanced texture — less rustic than hand hewn, smoother than rough sawn

- Refined appearance that works in both modern and traditional spaces

- Brings timeless character without the heavy rustic look

Are resawn box beams structural?

No — they’re decorative only. Resawn box beams are hollow and built to replicate the look of solid timbers without bearing weight.

Can they cover framing or HVAC?

Yes. Their hollow design makes them ideal for wrapping posts, pipes, or ducts, blending utility into design.

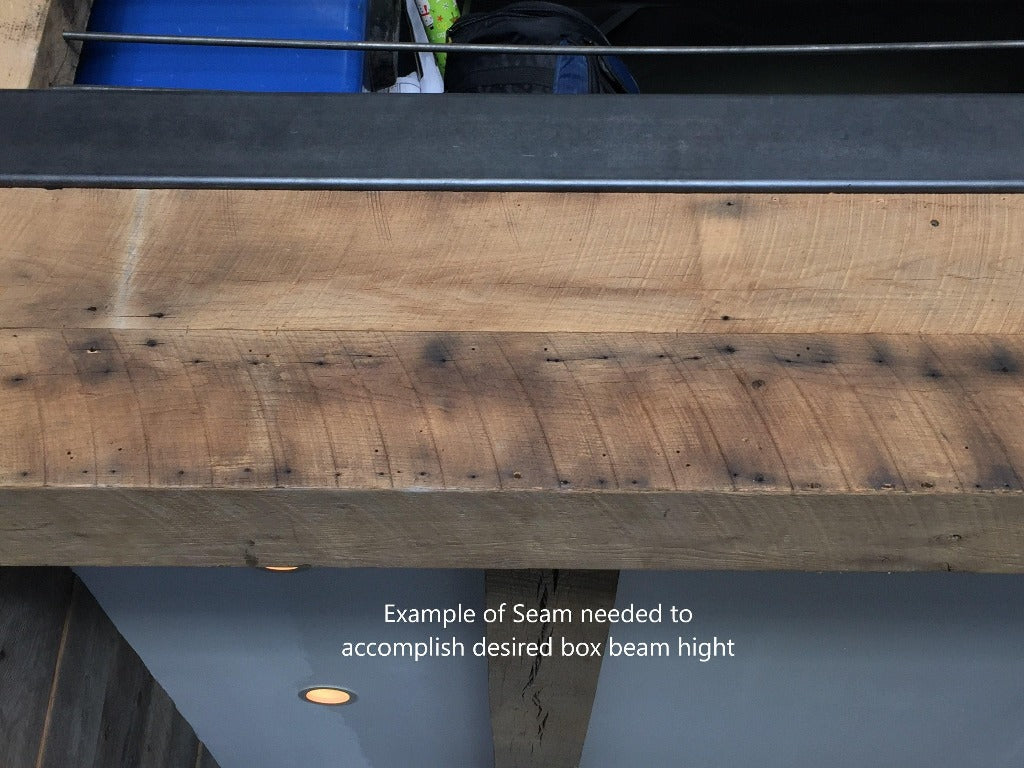

How are seams hidden?

With precise mitered joins and advanced craftsmanship, the corners align tightly so the beam looks like one solid piece.

Shipping & Lead Times

- Average lead time: 8–12 weeks

- Freight shipping required for beams over 106”

- Shipping quoted separately before delivery