Do Cost More Than Solid Beams?

Many factors go into the cost of a including; box beam dimensions, selection, additional -work such as staining or waxing, and many more factors, however a is always more expensive than a common

There are several ways to make a box beam. In our method which aims to replicate a solid beam as closely as possible, starts with a solid beam as the material source.

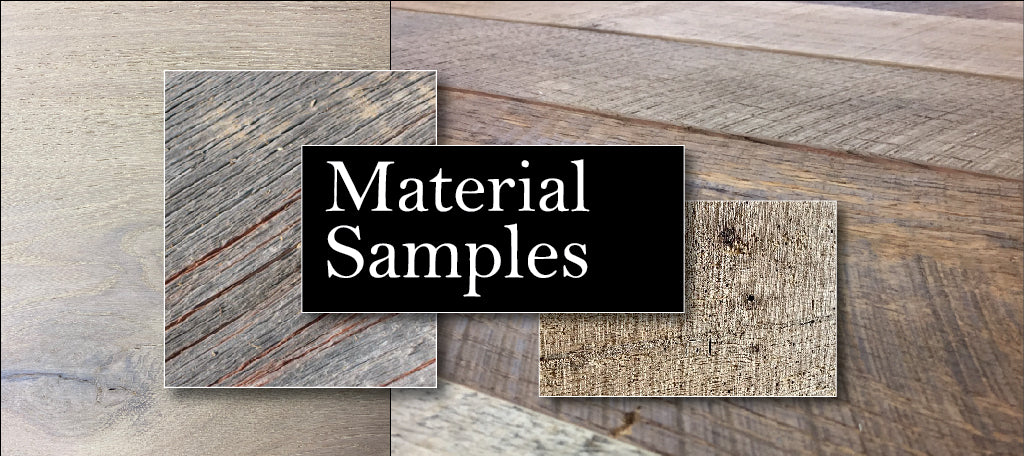

We have 30,000sf of solid beam material onsite to choose from

Our reclaimed wood box beams are made from a larger whose skins have been cut away to be used to build the new . Beam that is larger than the final box beam is used due to the margin needed to account for cuts.

Once we "skin" the larger solid beam, these skins will be patched and repaired as needed prior to being structurally fashioned together to form the final box beam shape. Most box beams are used for box beam ceilings so they are three-sided, as in the images here.

Once the structure is complete, the artwork begins. Our Craftsmen meticulously work the seams and character marks to ensure continuity. We're known for our nearly impossible to see corner seams.

This is just a portion of what there is to know about a wood box beam. Learn everything you need to know before pulling the trigger on buying a box beam by reading our all in one top tips on wood box beams here.

0 comments