hewn, rough sawn, and new wood box beams.

Box beams are an extremely useful way of achieving a solid beam look, built to exact sizing, and without the weight. Here's what you need to know.

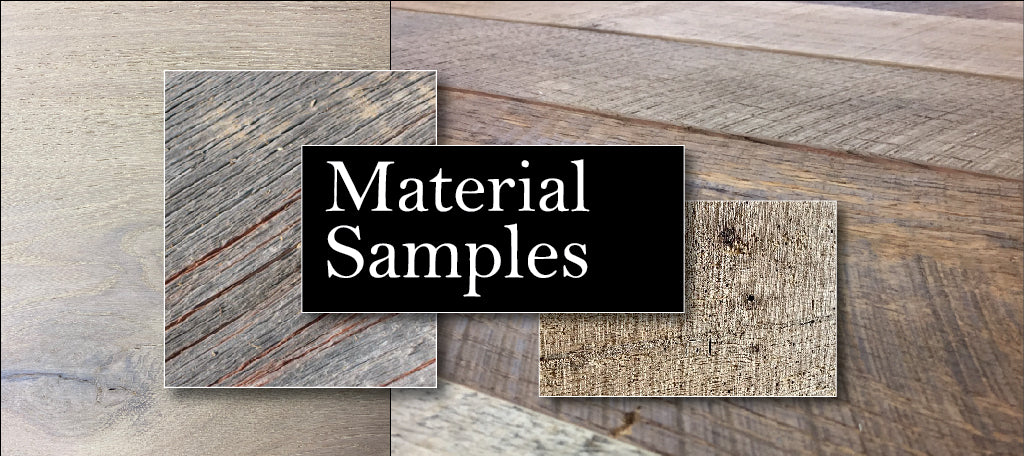

Regardless of your selection, our craftsmen with over 200 years of experience between them will create the perfect for your custom project always using that is either newly harvested or antique/. All of our are , there's nothing fake about it. We don't care for the term "" because the term lacks the respect for the hours of craftsmanship that we put into each . We produce in a variety of but it usually comes down to choices driving the difference:

1. What kinds of box beams are there

- Hewn : the most rustic of textures. These dimensional beams were cut, using tools like broad axes and adzes to chop away the excess ; turning a round tree log into a square or rectangular

- Rough Sawn : With the advent of powered machine driven circular saws, rough sawn became ubiquitous. milled with circular saws a century ago often left behind circle saw marks, by they cut marks, impressions, or burn marks.

- Resawn : Resawn may also be called live sawn. When resawing the original face away, the core is what is left. This resawn core has a nearly smooth face on all sides. This is the ideal type of to sand smooth and apply a or custom translucent , allowing the beautiful old growth tight grain to show through.

- New Euro White Oak : When creating a from newly harvested , the process of creating a is the same; resawing an appearance layer from a thicker plank, engineering to Baltic Birch and joining. A popular choice for new is . Almost always, our clients choose a custom for these beams, usually to complement their floors and stairs.

2. How is a Different than a ?

As opposed to or , to make reclaimed barn , we resaw the original face away from the core of the . These original face skins are engineered to the finest Baltic Birch for strength and structure, then marry the sections; reinforcing the sides with internal blocking. Seeing the true artistry of a well-done reclaimed is a real treat. Our Craftsmen are able to hide the corner and and even cut in grain by so there is no discernable difference in grain at the joints. This is why our clients often think we hollowed out a to create their ; because the joints are imperceptible.

To make from newly harvested , we resaw a thick layer of from a thicker plank, then create the as usual.

3. Where are used?

Choosing a custom made not only looks great but has functional appeal as well. are often what you see in a , protruding down from the . A is also used to wrap unappealing structural elements like pipes or I-beams, framing, or HVAC in a building. Installation is far easier as well since the are lighter, can be easily trimmed or modified to fit with tools on the job site, and the weight is far less than a allowing for greater spans without significant support. As well, they are a great alternative to solid beams in applications which preclude the use of heavier solid beams. People even use them vertically as elements to further replicate an endoskeleton of a frame building.

4. Do Cost the Same as Solid Beams?

Many factors go into the cost of a including; dimensions, selection, -work, and many more factors however a is always more expensive than a . A is purely made from a larger whose four skins have been cut away to be used to build the new . This addition of the extensive labor involved in crafting such a . This is in addition to the cost of the host from which the original face skin is taken.

5. How Big Can You Make a ?

There isn't a size we haven't built. With our massive inventory and experience in architectural elements, we'll likely be able to create what others may not due to limitations in their access or ability. We make with respect to , depth, and with some beams spanning longer than 30 feet.

This is just a portion of what there is to know about a wood box beam. Learn everything you need to know before pulling the trigger on buying a box beam by reading our all in one top tips on wood box beams, be sure to check out our Faux Wood Beams - Ultimate Box Beam Ceiling Buyer's Guide

0 comments